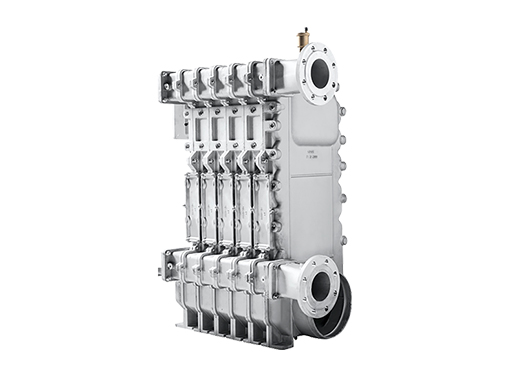

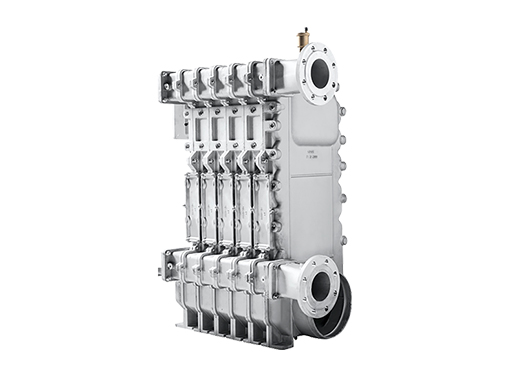

This product is independently developed, designed and manufactured by Bowei Company; the material used is strictly in accordance with the European standard EN-AC43000, using silicon-aluminum alloy materials; it adopts excellent casting technology, one-time molding...

Tel:

+86-0372-2715235Whatsapp:

+86177967229751.The integral cast aluminum heat exchanger is adopted, which has high heat conduction efficiency, strong corrosion resistance and low noise;

2. Mature equipment technology (parts imported from Europe, safe and reliable, stable operation, service life up to 30 years);

3. Central constant temperature control, flexible installation, remote control, digital display microcomputer intelligent control (simple operation, saving personnel management, low maintenance cost); ultra-low emission: NOx emission is as low as 30mg/m3 or less (lower than national requirements Emission Standards);

4. Condensation technology, multiple protections, low operating costs (saving 30%-50% compared to traditional heating and central air-conditioning equipment);

5. Small footprint (1.5-3 square meters), easy to install;

6. The combustion chamber is fully water-cooled, with parallel water channels, low water flow resistance, and integrated rib-column combination for heat exchange and condensation of the flue system;

7. Small size, light weight, easy to transport and install;

8. Multiple modules can be combined in parallel;

The thermal efficiency of the cast aluminum condensing boiler is more than 35% higher than that of ordinary boilers, up to 108%.

The NOx emission per cubic meter under the standard working condition is less than 30㎎/m³, which is in line with China's increasingly stringent NOx emission standards.

Small size, light weight, wheel support, use PVC pipe to increase the service life of the smoke pipe, easy to install

Intelligent control, precise temperature control, multiple safety protections, and imported high-end accessories ensure safe and reliable operation

The powerful intelligent control system and perfect product after-sales service system ensure that users can feel at ease during use.

Synchronized with European advanced technology, in line with European standards, core components such as cast aluminum heat exchangers are designed to have a long service life

Taking the 1100KW boiler model as an example, it covers an area of about 2 square meters, and the heating area can reach more than 20,000 square meters.

Low cost, long life, simple structure, high quality accessories, strong versatility, less wearing parts, easy maintenance.

| Heat Exchanger Size | |||

| Model | Length(mm) | Width(mm) | Height(mm) |

| 90KW | 510 | 400 | 900 |

| 120KW | 510 | 400 | 900 |

| 175KW | 595 | 400 | 900 |

| 220KW | 680 | 400 | 900 |

| 275KW | 765 | 400 | 900 |

| 320KW | 850 | 400 | 900 |

| 550KW | 935 | 400 | 900 |

| 700KW | 1065 | 600 | 1150 |

| 1100KW | 1250 | 600 | 1150 |

| 1400KW | 1530 | 600 | 1150 |

| 1750KW | 1910 | 600 | 1150 |

| 2100KW | 1730 | 1000 | 1550 |

| 2800KW | 1980 | 1000 | 1550 |

Please contact us for free quotation by form below. We promise the quickest response within 24 hours: